80-200Micron TPU Polyurethane DTF Powder Adhesive DTF Hot Melt

Powder for Heat Transfer

DTF Hot Melt Powder Description

DTF Hot Melt Powder is thermoplastic polyurethane powder hot melt

adhesive. The product has a soft feel, good resilience,

stretchability, and excellent low-temperature processability.

Excellent adhesion to textiles.

In the DTF process, a special ink is printed onto a heat-resistant

PET film, and then the DTF Hot Melt Powder is applied to the wet

ink. The powder adheres to the ink and acts as a bonding agent.

Excess powder is removed, leaving the desired design on the film.

The next step involves transferring the design from the film to the

fabric. The printed film is placed on top of the fabric, and heat

is applied using a heat press or conveyor dryer. The heat activates

the DTF Hot Melt Powder, causing it to melt and bond the ink with

the fabric fibers. After the application of heat, the film is

peeled off, leaving the printed design on the fabric.

DTF Hot Melt Powder Physical Characteristics

Appearance | White powder |

Composition | Polyurethane |

Hardness | 80±3 Shore A |

Melting Point DSC | 95-115 ℃ |

MI Index ASTM D-1238 | 30±7 g/10min |

Resistance to yellowing (level) | 2.0-3.0 |

DTF Hot Melt PowderTechnical Parameters

Bonding Parameters

( reference only) | Temperature | 110-130℃ |

Press | 1.5-2.5 kg/cm2 |

Time | 8-15S |

Washing Resistance | 40℃ | Excellent |

60℃ | General |

90℃ | / |

Attention

1. Must be stored in dry unopened package. High temperature and

pressure will cause agglomeration. The trays cannot bedouble-pressed.

2. Bonding temperature and pressure and time relate to the bonding

strength of the film to the material. The bonding temperature must

be close to the temperature set by the machine, the pressure must

be uniform, and the mold and press rolls must be flat.

3. The bonding conditions used will vary between machines and

materials. The conditions indicated here are only basic. The most

ideal bonding conditions should be established by manufacturing for

the specific application.

DTF Hot Melt Powder Application

DTF Hot Melt Powder can be used in DTF, textile and garment, thermal transfer printing,

thermal transfer paste, flocking paste, bronzing paste.

DTF Hot Melt Powder offers several advantages in the DTF printing

process. It provides strong adhesion between the ink and fabric,

resulting in durable and long-lasting prints. The powder also

allows for fine details and vibrant colors in the printed designs.

Additionally, DTF printing with hot melt powder is compatible with

a wide range of fabrics, making it suitable for various

applications such as apparel, accessories, and promotional items.

DTF Hot Melt Powder FAQ

Q1). How about your conventional package and the MOQ of your adhesive

powder?

We have 1kg and 20kg per bag,MOQ is 20kg.

Q2). What is your lead time ?

3-5 days , depending on the quantity , we almost have safe stock.

Q3). Do you provide free sample? And how many days it will take?

Yes, we can provide 300g free sample, only need you to pay the

shipping cost. We will make the sample within 1- 2 working days and

it will take 3-5days on the transportation.

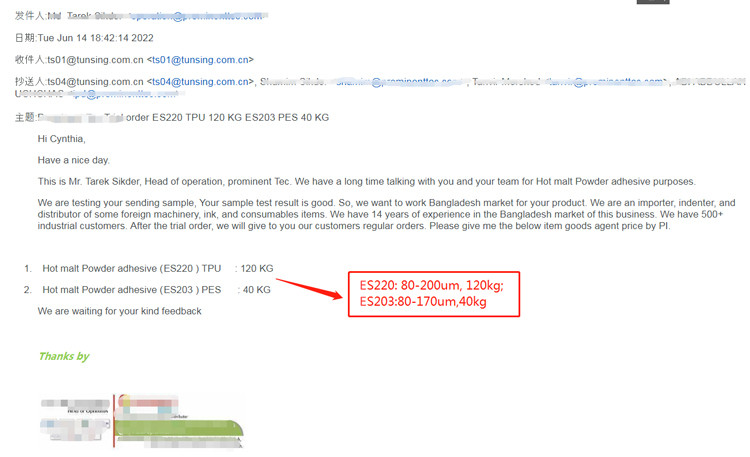

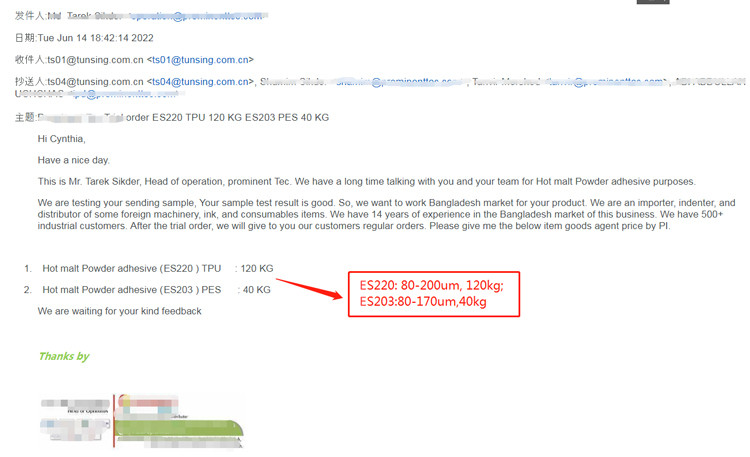

DTF Hot Melt Powder Buyer Feedback

DTF Hot Melt Powder Package and Delivery

Pacage Details: 1kg, 2kg, 5kg, 20kg/bag

Delivery: Shipped in 3-7 working days after receive payment